This article answers the question how to drill a straight hole without a drill press.

A drill press makes it easy for you when you need to drill straight. However, in some cases you may not be able to use it. In these situations, you will need to use some tricks to drill properly with an electric drill.

Practice to drill straight

Drilling straight can be a habit. Therefore, if you want to be independent of any material that simplifies this task, practice. First, make sure the material is still. Use a shim if necessary to avoid vibrations that could destabilize your work. Also make sure your drill is sharp and set correctly. Then start drilling, using both hands to hold the device firmly.

As soon as the drill begins to penetrate the material, let yourself be guided by its movement while ensuring that its progression is straight. Once your hole is well drilled, you can remove the device. If this is your first try, the odds of hitting a straight hole will be low.

On the other hand, if you got it right the first time, do not think that it will be the case for the next jobs. Even with hours of practice, you may still make a mistake. The only solution will then be to practice relentlessly and not to take into account too much the few mistakes that could happen.

For those who don’t have enough time to practice and those who don’t feel like it, easy solutions exist. Among them is the drill press . However, this device also has its limitations and you will then need to resort to a standard drill. Homemade solutions and paid options exist to help you drill straight without necessarily having the experience of a pro.

Make your own drilling guides

The easiest way is to use a drill guide that allows you to line up in the direction you want. You can DIY this type of tool yourself in order to drill straight up and down, left to right or in all directions.

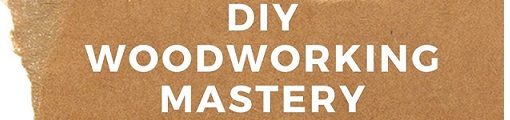

The first solution is to glue two straight pieces of wood perpendicularly. You can also cut a piece of cleat at a right angle to get this tool. To drill straight, all you have to do is place the bit on the angle formed by the guide. Be careful not to tilt your drill, as this may damage your fence and you will not get a straight result.

In a way, if you haven’t damaged your guide, your hole will be successful. This solution will allow you to align your drill in all directions. For a less precise solution, but just as easy to set up, use a drill mirror.

You can use a CD as long as its reflective side is still in good condition. To use it, insert the bit through the hole in the middle of the CD. The reflection of your wick should therefore be visible, in a blurry manner, on the reflective surface.

Then you just have to align the bit with its reflection to get a straight hole in all four directions.

A more original solution, but much less precise, consists in using a weighted washer. You will need to connect two nuts or other similar tools with a wire. When drilling, place the washer on the bit. If it is not straight, then this one will slide with the other washer which is at the end of the wire.

If the bit is straight, it will stand still. This solution only allows you to align your holes from top to bottom. If you are using your drill vertically or at a necessarily inclined angle, the other two guides mentioned above will be more appropriate.

For better accuracy, you can also use a router. However, you will only be able to use it on compatible materials. In addition, you will need a straight cutter with a small diameter and shallow drilling depth.

Paid solutions for how to drill a straight hole without a drill press

Since straight drilling is a common DIY problem, ready-made, out-of-the-box solutions have sprung up.

Special Drilling Blocks

There are for example the special drilling blocks. They are plastic blocks in which holes made of stronger materials are embedded and serve as a guide. There are often multiple guides present to allow use with a wide variety of drill heads.

However, these guides have a standard diameter which could in some cases differ from that of your drill bit. Despite its aesthetic appearance, it sometimes happens that the metals made guides start to rust. Fortunately, their use will not be affected.

They will allow drilling at a right angle and can also be used on tubes. Their price is not exceptional, but given the simplistic design of the guides, you might still be reluctant to buy one.

Embedded systems in products

Some drill manufacturers have decided to build a system directly into their products that can help drill straight. It is simply a spirit level. When the drill is tilted the bubble will move to one of the edges of its container and when straight it will be in the middle.

This type of accessory will not, however, help you to properly adjust your hole if you are using your drill vertically.

If you need precision in many working angles then the tool for you is a special drill guide. Just place it on the device and then set the working angle you want. This angle will also be reproducible elsewhere whether it is perpendicular or not.

Finally, if you are looking for a fun and useful option for your drill press, go for a laser alignment system. On a device placed on the drill bit, a laser emits a beam towards the material you wish to drill. As the drill bit rotates, the laser follows the movement and eventually draws a circle.

In order to drill straight, all you have to do is adjust your drill so that the drawn circle is round.

Further Reading

What are essential woodworking tools for beginners